FA-HS Series Electrostatic Hair Separator Designed for the Food Industry Reliable Separation of Hair/Paper/Fiber/Dust, etc Impurities

Product Highlights

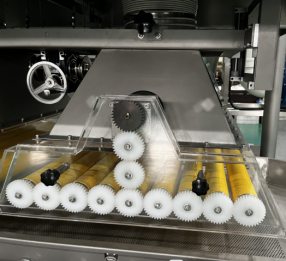

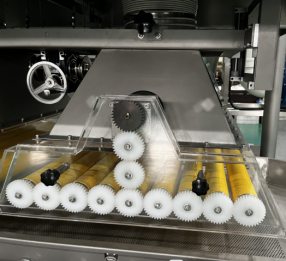

-Double sets of 18 electrostatic zone design, optional bipolar electric field, better impurity removal performance

-Optional strong magnetic iron removal device

-Both conveying and adsorption devices can be adjusted

-Optional auxiliary air delivery system to facilitate the discharge of debris

-Self-contained sub-filters for purification and environmental protection

-Optional dust cyclone separator

-SUS304 frame and major hardware parts by CNC tooling.

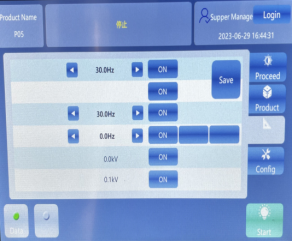

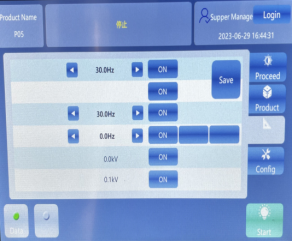

-Touch screen user interface for easy operation according to material management parameters.

Customized models equipment can remove sticky and easy-to-adhesive dander and foreign matter on the surface of the material is oily or sugary.

-Dual-sets 18 high-stability electrostatic filed

with core patented invention of "dual-set 18 high-stability electrostatic filed", designed to separate hair, fibre, paper dust and fine particles in bulk materials such as fruits and vegetables, seaweed, edible mushrooms, tea leaves, herbs, nuts, etc.

-Very High Production Capacity with Accurate Separation Rate

Its capacity can reach 2500L/H at a 99% accurate separation out rate.

-10” Colour Touchscreen

Touch screen user interface for easy operation according to material management parameters.

Typical Products Application

1. Seaweed

2.Dehydrated Vegetables

3.Casual Fried Food

4.Vegetables and Fruits

5.Nuts

6.Dried/Preserved Fruits

7.Slices and Granules

8.Fungus

9.Hazel Mushrooms

10.Edible Fungi

Rubber and Plastic Products

Technical Specifications

Model | FA-HS600 | FA-HS1200 |

Capacity(L/H) | 2500 | |

Conveyor Tray Width(mm) | 600 | 1200 |

Suction Disc Height(mm) | 60-150(adjustable) | 60-150(adjustable) |

Conveyor Tray Length(mm) | 2200 | |

Conveyor Belt Height(from top surface to ground) | 750+100mm(can be customized) | |

Filter Efficiency | ≥99% | |

Material of Construction | 304 Brushed stainless steel | |

Auto Set-up Function | Guided Auto-setup | |

Power Supply | 3N-50HZ 380V±10%, three-phase five-wire system (good grounding must be ensured) | |

Electrostatic Working Voltage | 6-25Kv | |

| Power Consumption | 3.7KW | |

Working Environment | Normal temperature, humidity RH<80%, clean air, dust does not contain harmful substances which will corrode the equipment. | |

Equipment Working Noise | ≤55dB | |

Optional Features | Dust Handling Device Magnetic Metal Remover Auxiliary Air Supply Buoyancy System Bipolar Electric Field | |

* The actual detection and separation effect is related to the type, temperature and water content of the detected product, as well as the application environment

Reference Pi

Product Highlights

-Double sets of 18 electrostatic zone design, optional bipolar electric field, better impurity removal performance

-Optional strong magnetic iron removal device

-Both conveying and adsorption devices can be adjusted

-Optional auxiliary air delivery system to facilitate the discharge of debris

-Self-contained sub-filters for purification and environmental protection

-Optional dust cyclone separator

-SUS304 frame and major hardware parts by CNC tooling.

-Touch screen user interface for easy operation according to material management parameters.

Customized models equipment can remove sticky and easy-to-adhesive dander and foreign matter on the surface of the material is oily or sugary.

-Dual-sets 18 high-stability electrostatic filed

with core patented invention of "dual-set 18 high-stability electrostatic filed", designed to separate hair, fibre, paper dust and fine particles in bulk materials such as fruits and vegetables, seaweed, edible mushrooms, tea leaves, herbs, nuts, etc.

-Very High Production Capacity with Accurate Separation Rate

Its capacity can reach 2500L/H at a 99% accurate separation out rate.

-10” Colour Touchscreen

Touch screen user interface for easy operation according to material management parameters.

Typical Products Application

1. Seaweed

2.Dehydrated Vegetables

3.Casual Fried Food

4.Vegetables and Fruits

5.Nuts

6.Dried/Preserved Fruits

7.Slices and Granules

8.Fungus

9.Hazel Mushrooms

10.Edible Fungi

Rubber and Plastic Products

Technical Specifications

Model | FA-HS600 | FA-HS1200 |

Capacity(L/H) | 2500 | |

Conveyor Tray Width(mm) | 600 | 1200 |

Suction Disc Height(mm) | 60-150(adjustable) | 60-150(adjustable) |

Conveyor Tray Length(mm) | 2200 | |

Conveyor Belt Height(from top surface to ground) | 750+100mm(can be customized) | |

Filter Efficiency | ≥99% | |

Material of Construction | 304 Brushed stainless steel | |

Auto Set-up Function | Guided Auto-setup | |

Power Supply | 3N-50HZ 380V±10%, three-phase five-wire system (good grounding must be ensured) | |

Electrostatic Working Voltage | 6-25Kv | |

| Power Consumption | 3.7KW | |

Working Environment | Normal temperature, humidity RH<80%, clean air, dust does not contain harmful substances which will corrode the equipment. | |

Equipment Working Noise | ≤55dB | |

Optional Features | Dust Handling Device Magnetic Metal Remover Auxiliary Air Supply Buoyancy System Bipolar Electric Field | |

* The actual detection and separation effect is related to the type, temperature and water content of the detected product, as well as the application environment

Reference Pi