Fanchi-tech dual-view X-ray pallet scanner adopted our latest innovative technology, which facilitates operator to identify threat objects easily and accurately. It is designed for customers requiring inspection of large cargo, pallet, etc. The low conveyor allows for easy loading and unloading of cargos. Dual energy imaging provides automatic color coding of materials with different atomic numbers so that screeners can easily identify objects within the cargo.

Dual-view X-ray Banner/Luggage Scanner

Fanchi-tech dual-view X-ray pallet scanner adopted our latest innovative technology, which facilitates operator to identify threat objects easily and accurately. It is designed for customers requiring inspection of large cargo, pallet, etc. The low conveyor allows for easy loading and unloading of cargos. Dual energy imaging provides automatic color coding of materials with different atomic numbers so that screeners can easily identify objects within the cargo.

Features :

※ Large Cargo/Pallet Screening

※ Multi-language support

※ Dual-energy material discrimination

※ Assist to detect drug and explosive powder

※ Powerful X-ray source imaging performance and penetration

※ Extended height tunnel with square opening easily accepts outsized cargos

※ Ergonomically designed operating console features user-friendly

Specification:

Model | FA-XIS180180D | ||

Tunnel Size(mm) | 1810mm (W)×1810mm (H) | ||

Conveyor Speed | 0.20m/s | ||

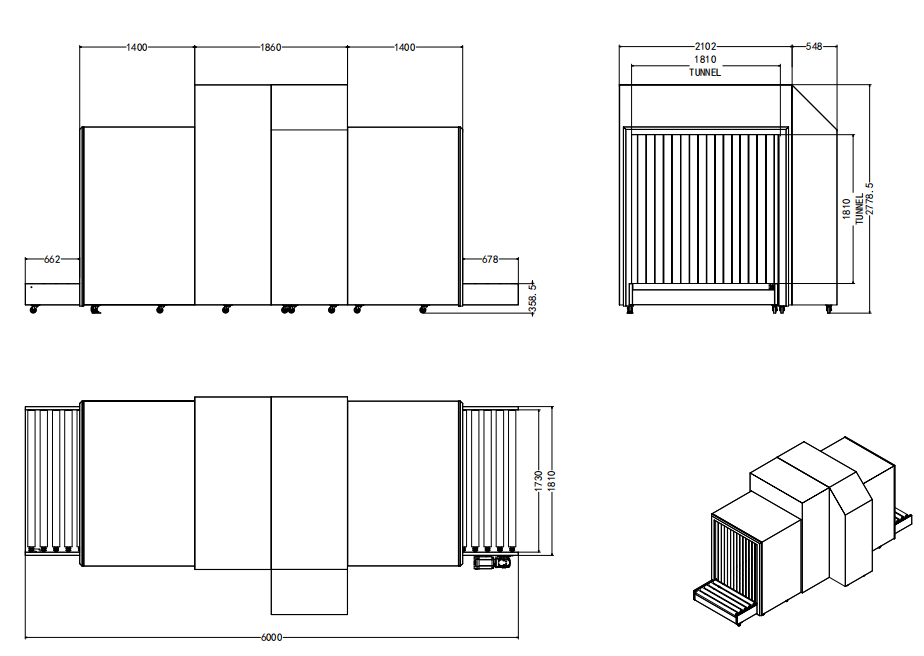

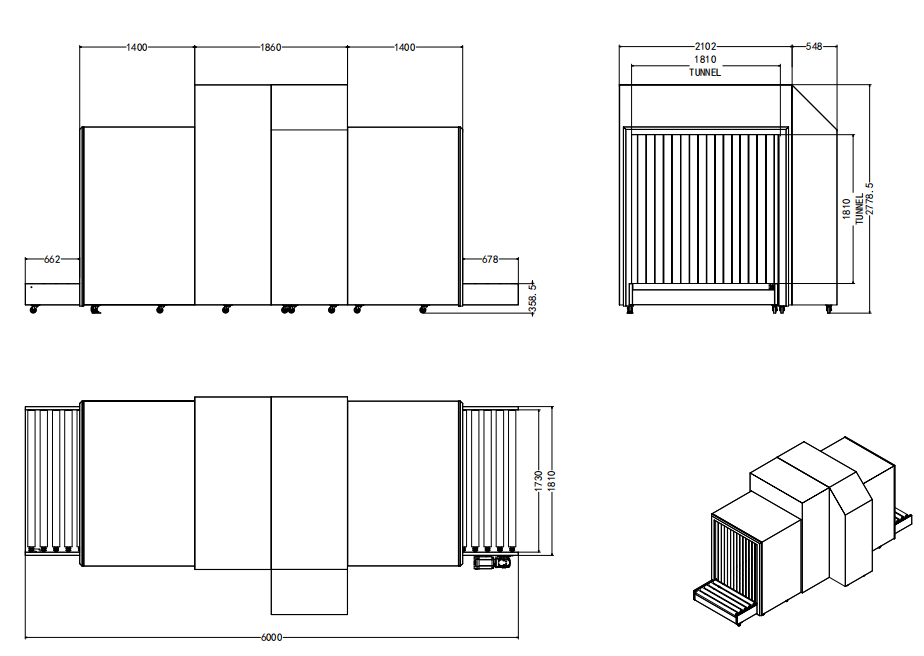

Dimensions | 6000mm(L)×2650mm (W)×2778.5mm (H) | ||

Max. Load | 3,500kg(even distribution) | ||

Line Resolution | 0.1mm/38AWG | ||

Spatial Resolution | HorizontalΦ1.3mm & VerticalΦ1.3mm | ||

Conveyor Type | Mechanical Rollers | ||

Penetrating | 50mm | ||

Monitor | 19-inch color monitor,resolution of 1280*1024 | ||

Anode Voltage | 260kV | ||

Cooling/Run Cycle | Oil cooling / 100% | ||

Max Radiation Leakage (5cm from housing) | 0.9μSv/h | ||

X-Ray Resource Number | 2 | ||

Multi-energetic Distinguish Objects | 3 colors alarm and separation according to atomic number: Organic objects in orange, inorganic objects in blue, mixture in green | ||

Selection and Magnification | Variable zoom up to X64,support continuous magnification | ||

Image Playback | checked images playback | ||

Storage Capacity | 100,000 images | ||

Film Safety | In full compliance with the ASA/ISO1600 film safe standard | ||

System Functions | High-density alarm,Auxiliary examination of drugs and explosive,TIP(threat image projection);Date/time display,Baggage counter,User management,system timing, Ray-beam timing, Power on self-test, Image back-up and search,Maintenance and diagnosis,,Bi-directional scanning. | ||

Optional Functions | Video monitoring system/ LED( liquid crystal display)/Energy-conservation and environmental -protection equipment / Electronic weighing system etc | ||

Storage Temperature | -40℃±3℃~+60℃±2℃ | ||

Operating Temperature | 0℃~+40℃ | ||

Operation Voltage | 220 VAC(+/-10%), 50/60HZ | ||

Power Consumption | 3kVA | ||

Options | UPS, Standard Test Objects | ||

Drawing for Reference :

Dual-view X-ray Banner/Luggage Scanner

Fanchi-tech dual-view X-ray pallet scanner adopted our latest innovative technology, which facilitates operator to identify threat objects easily and accurately. It is designed for customers requiring inspection of large cargo, pallet, etc. The low conveyor allows for easy loading and unloading of cargos. Dual energy imaging provides automatic color coding of materials with different atomic numbers so that screeners can easily identify objects within the cargo.

Features :

※ Large Cargo/Pallet Screening

※ Multi-language support

※ Dual-energy material discrimination

※ Assist to detect drug and explosive powder

※ Powerful X-ray source imaging performance and penetration

※ Extended height tunnel with square opening easily accepts outsized cargos

※ Ergonomically designed operating console features user-friendly

Specification:

Model | FA-XIS180180D | ||

Tunnel Size(mm) | 1810mm (W)×1810mm (H) | ||

Conveyor Speed | 0.20m/s | ||

Dimensions | 6000mm(L)×2650mm (W)×2778.5mm (H) | ||

Max. Load | 3,500kg(even distribution) | ||

Line Resolution | 0.1mm/38AWG | ||

Spatial Resolution | HorizontalΦ1.3mm & VerticalΦ1.3mm | ||

Conveyor Type | Mechanical Rollers | ||

Penetrating | 50mm | ||

Monitor | 19-inch color monitor,resolution of 1280*1024 | ||

Anode Voltage | 260kV | ||

Cooling/Run Cycle | Oil cooling / 100% | ||

Max Radiation Leakage (5cm from housing) | 0.9μSv/h | ||

X-Ray Resource Number | 2 | ||

Multi-energetic Distinguish Objects | 3 colors alarm and separation according to atomic number: Organic objects in orange, inorganic objects in blue, mixture in green | ||

Selection and Magnification | Variable zoom up to X64,support continuous magnification | ||

Image Playback | checked images playback | ||

Storage Capacity | 100,000 images | ||

Film Safety | In full compliance with the ASA/ISO1600 film safe standard | ||

System Functions | High-density alarm,Auxiliary examination of drugs and explosive,TIP(threat image projection);Date/time display,Baggage counter,User management,system timing, Ray-beam timing, Power on self-test, Image back-up and search,Maintenance and diagnosis,,Bi-directional scanning. | ||

Optional Functions | Video monitoring system/ LED( liquid crystal display)/Energy-conservation and environmental -protection equipment / Electronic weighing system etc | ||

Storage Temperature | -40℃±3℃~+60℃±2℃ | ||

Operating Temperature | 0℃~+40℃ | ||

Operation Voltage | 220 VAC(+/-10%), 50/60HZ | ||

Power Consumption | 3kVA | ||

Options | UPS, Standard Test Objects | ||

Drawing for Reference :