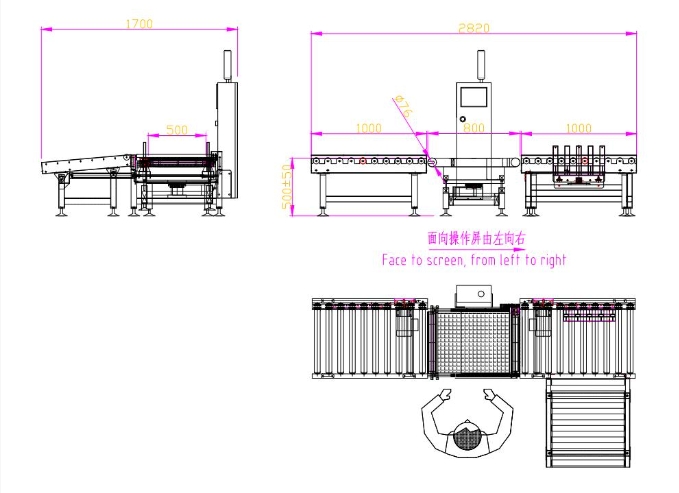

FA-CW Series Checkweigher for large package products

Video Clips: https://www.youtube.com/watch?v=ueA6ToXE-84Overview:

Fanchi-tech Checkweigher has been widely applied in various industries like: meat&poultry processing, sea food, bakery, nuts, vegetables, pharmacy, cosmetics, etc. Weigh, count and reject in a single, non-stop checkweighing solution. Weigh large, heavy packages without stopping or recalibrating the conveyor. With a Fanchi-tech checkweigher customized to your specifications, you can depend on accurate weight control, maximized efficiency, and consistent product throughput, even in rugged industrial environments. From raw or frozen products, bags, cases or barrels to mailers, totes and cases, we will keep your line moving toward maximum productivity at all times.

Product Highlights

1.Accurate and efficient rejection system.

2.Switch Products in Seconds with a Library of Stored Products up to 100

3.Brushless motors & proven conveyor components designed for reliable 24/7 operation

4.High precision digital load cell, adopt high-speed digital filtering processing technology;

5.Further weighing stability by platform positioning rail and enhanced conveying / weighing platforms.

6.Ultra-fast dynamic weight tracking and automatic compensation technology effectively Improve the detection of stability.;

7.Simple Operation with color touch screen, including multilevel password access and data logged events to aid traceability

8.For dynamic weighing of large end-of-line packaged goods including convenience foods, sachets and ready meals

9.Fast, Simple & Accurate Setup: type in your product details, initiate setup, and pass a pack several times and the FA-CW is automatically set-up and ready to use

Key Components

● German HBM high speed load cell

● Japanese Oriental motor

● Danish Danfoss frequency converter

● Japanese Omron Optic sensors

● French Schneider Electric Unit

● US Gates synchronous belt

● Japanese SMC pneumatic unit

● Weinview industrial touch screen

Specification:

| Model | FA-CW500 | FA-CW600 | FA-CW700 |

| Deceting Range | 0.1~25kg | 0.1~50kg | 0.1~60kg |

| Scale interval | 1g | 1g | 1g |

| Deceting Accuracy | ±10g | ±25g | ±25g |

| Deceting Speed | 40pcs/min | 35pcs/min | 35pcs/min |

| Weigher Size(W*Lmm) | 500x600/800 | 600x1280 | 700x1280 |

Material of | Stainless Steel 304 | ||

| Belt Type | PU Anti Static | ||

| Line Height Options | 600,650,700,750,800,850,900mm +/- 50mm(can be customized) | ||

| Operation Screen | 7-inch LCD Touch Screen | ||

| Memory | 100 Kinds | ||

| Weigh Sensor | HBM high accuracy load cell | ||

| Rejector | Heavy Pusher Rejector | ||

| Air Supply | 5 to 8 Bar (10mm Outside Dia) 72-116 PSI | ||

Operating | 0-40℃ | ||

| Self-diagnosis | Zero error, photosensor error, setting error, products too close error. | ||

Other Standard | Windshield cover(colorless and clear), photo sensor; | ||

| Power Supply | AC110/220V, 1phase, 50/60Hz, 750W | ||

| Data Retrieval | Via USB(standard), Ethernet is optional | ||

Note:

1. The technical parameter above namely is the result of accuracy by checking only the test sample on the belt. The accuracy would be affected according to the detecting speed and product weight.

2. The detecting speed above will be affected according to the product size to be checked.

3. We much appreciate if you attach the filled product info questionnaire with your enquiry.

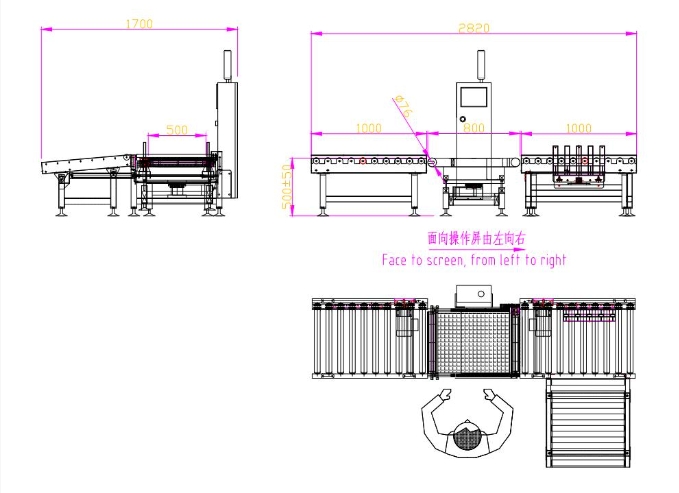

FA-CW Series Checkweigher for large package products

Video Clips: https://www.youtube.com/watch?v=ueA6ToXE-84Overview:

Fanchi-tech Checkweigher has been widely applied in various industries like: meat&poultry processing, sea food, bakery, nuts, vegetables, pharmacy, cosmetics, etc. Weigh, count and reject in a single, non-stop checkweighing solution. Weigh large, heavy packages without stopping or recalibrating the conveyor. With a Fanchi-tech checkweigher customized to your specifications, you can depend on accurate weight control, maximized efficiency, and consistent product throughput, even in rugged industrial environments. From raw or frozen products, bags, cases or barrels to mailers, totes and cases, we will keep your line moving toward maximum productivity at all times.

Product Highlights

1.Accurate and efficient rejection system.

2.Switch Products in Seconds with a Library of Stored Products up to 100

3.Brushless motors & proven conveyor components designed for reliable 24/7 operation

4.High precision digital load cell, adopt high-speed digital filtering processing technology;

5.Further weighing stability by platform positioning rail and enhanced conveying / weighing platforms.

6.Ultra-fast dynamic weight tracking and automatic compensation technology effectively Improve the detection of stability.;

7.Simple Operation with color touch screen, including multilevel password access and data logged events to aid traceability

8.For dynamic weighing of large end-of-line packaged goods including convenience foods, sachets and ready meals

9.Fast, Simple & Accurate Setup: type in your product details, initiate setup, and pass a pack several times and the FA-CW is automatically set-up and ready to use

Key Components

● German HBM high speed load cell

● Japanese Oriental motor

● Danish Danfoss frequency converter

● Japanese Omron Optic sensors

● French Schneider Electric Unit

● US Gates synchronous belt

● Japanese SMC pneumatic unit

● Weinview industrial touch screen

Specification:

| Model | FA-CW500 | FA-CW600 | FA-CW700 |

| Deceting Range | 0.1~25kg | 0.1~50kg | 0.1~60kg |

| Scale interval | 1g | 1g | 1g |

| Deceting Accuracy | ±10g | ±25g | ±25g |

| Deceting Speed | 40pcs/min | 35pcs/min | 35pcs/min |

| Weigher Size(W*Lmm) | 500x600/800 | 600x1280 | 700x1280 |

Material of | Stainless Steel 304 | ||

| Belt Type | PU Anti Static | ||

| Line Height Options | 600,650,700,750,800,850,900mm +/- 50mm(can be customized) | ||

| Operation Screen | 7-inch LCD Touch Screen | ||

| Memory | 100 Kinds | ||

| Weigh Sensor | HBM high accuracy load cell | ||

| Rejector | Heavy Pusher Rejector | ||

| Air Supply | 5 to 8 Bar (10mm Outside Dia) 72-116 PSI | ||

Operating | 0-40℃ | ||

| Self-diagnosis | Zero error, photosensor error, setting error, products too close error. | ||

Other Standard | Windshield cover(colorless and clear), photo sensor; | ||

| Power Supply | AC110/220V, 1phase, 50/60Hz, 750W | ||

| Data Retrieval | Via USB(standard), Ethernet is optional | ||

Note:

1. The technical parameter above namely is the result of accuracy by checking only the test sample on the belt. The accuracy would be affected according to the detecting speed and product weight.

2. The detecting speed above will be affected according to the product size to be checked.

3. We much appreciate if you attach the filled product info questionnaire with your enquiry.