Gravity Fall Metal Detector with best sensitivity, fully compliant with HACCP requirements.

Gravity Fall Metal Detector

Fanchi-tech FA-MD-P Series Metal Detector is a gravity fed / throat metal detector system designed for inspecting bulk, powders and granules. It is ideal for checking early in the production process to detect metal before the product moves down the line, minimising the potential cost of wastage and protecting other processing equipment. Its sensitive sensors detect even the smallest metal contaminants, and fast-switching separation flaps discharge them directly from the product stream during production.

1.Reliably detects all type of metals in free-falling goods

2.Compact installation space by minimized metal-free zone

3.Auto parameter setting by intelligent product learning

4.Simple assembly due to mounting frame and quick release rings

5.Anti-interference photoelectric isolation drive allows remote installation of operation panel.

6.Higher interference proof by multi-filtering algorithm and X-R orthogonal decomposition algorithm.

7.Maximum inspection performance with highest reliability in the entire detection area due to hard-fill technology and adaptive DDS and DSP technology

Key Components

1. US Ramtron ferromagnetic RAM

2. US AD DDS Signal Generator

3. US AD low noise amplifier

4. ON Semi-conductor demodulation chip

5. Germany FESTO pneumatic rejection system

6. 7 inch Weinview HMI(optional)

Specification

| Nominal Diameters Available (mm) | 50(2”), 100 (4”), 150 (6”), 200 (8”), 250 (10”) | |||

| Material of Construction | 304 Brushed stainless steel | |||

| Metal Detection | Ferrous, non-ferrous (e.g. aluminum or copper) and stainless steel | |||

| Power Supply | 100-240 VAC, 50-60 Hz, 1 Ph, 50-60W | |||

| Temperature Range | 0 to 40° C | |||

| Humidity | 0 to 95% Relative Humidity (Non-condensing) | |||

| Product Memory | 100 | |||

| Maintenance | Maintenance-free, self-calibrating sensors | |||

| Operation Panel | Key Pad(Touch Screen is optional) | |||

| Software Language | English(Spanish/French/Russian, etc optional) | |||

| Conformity | CE (Declaration of Conformityand Declaration of Manufacturer) | |||

| CE (Declaration of Conformityand Declaration of Manufacturer) | Flap Rejector | |||

Note:

1. The detection aperture size can be made up to 250mm.

2. The technical parameter above namely is the result of sensitivity by detecting only the test sample on the belt. The sensitivity would be affected according to the products being detected, working condition and also the different positions the metal mixed with.

3. Detecting capacity per hour is related with product weight, the value of the table is according to the density of water (1000kg /m3).

4. We much appreciate if you attach the filled product info questionnaire with your enquiry.

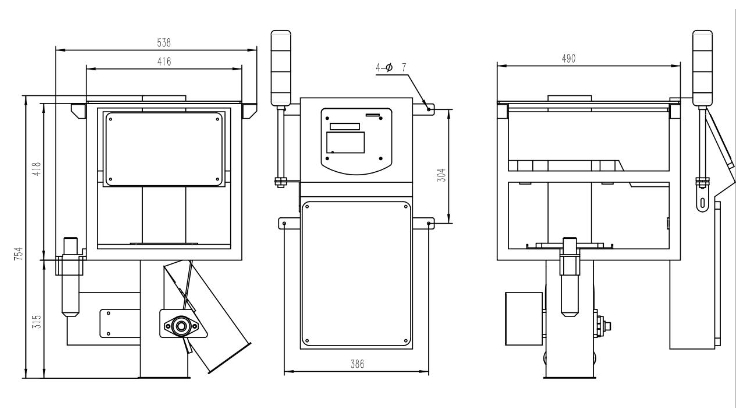

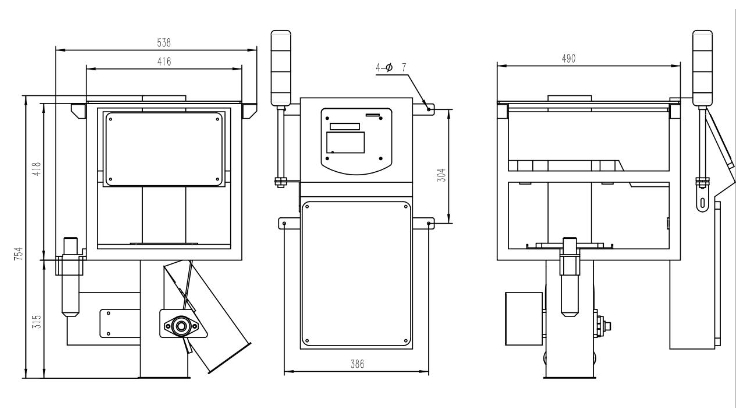

Size Layout

Gravity Fall Metal Detector

Fanchi-tech FA-MD-P Series Metal Detector is a gravity fed / throat metal detector system designed for inspecting bulk, powders and granules. It is ideal for checking early in the production process to detect metal before the product moves down the line, minimising the potential cost of wastage and protecting other processing equipment. Its sensitive sensors detect even the smallest metal contaminants, and fast-switching separation flaps discharge them directly from the product stream during production.

1.Reliably detects all type of metals in free-falling goods

2.Compact installation space by minimized metal-free zone

3.Auto parameter setting by intelligent product learning

4.Simple assembly due to mounting frame and quick release rings

5.Anti-interference photoelectric isolation drive allows remote installation of operation panel.

6.Higher interference proof by multi-filtering algorithm and X-R orthogonal decomposition algorithm.

7.Maximum inspection performance with highest reliability in the entire detection area due to hard-fill technology and adaptive DDS and DSP technology

Key Components

1. US Ramtron ferromagnetic RAM

2. US AD DDS Signal Generator

3. US AD low noise amplifier

4. ON Semi-conductor demodulation chip

5. Germany FESTO pneumatic rejection system

6. 7 inch Weinview HMI(optional)

Specification

| Nominal Diameters Available (mm) | 50(2”), 100 (4”), 150 (6”), 200 (8”), 250 (10”) | |||

| Material of Construction | 304 Brushed stainless steel | |||

| Metal Detection | Ferrous, non-ferrous (e.g. aluminum or copper) and stainless steel | |||

| Power Supply | 100-240 VAC, 50-60 Hz, 1 Ph, 50-60W | |||

| Temperature Range | 0 to 40° C | |||

| Humidity | 0 to 95% Relative Humidity (Non-condensing) | |||

| Product Memory | 100 | |||

| Maintenance | Maintenance-free, self-calibrating sensors | |||

| Operation Panel | Key Pad(Touch Screen is optional) | |||

| Software Language | English(Spanish/French/Russian, etc optional) | |||

| Conformity | CE (Declaration of Conformityand Declaration of Manufacturer) | |||

| CE (Declaration of Conformityand Declaration of Manufacturer) | Flap Rejector | |||

Note:

1. The detection aperture size can be made up to 250mm.

2. The technical parameter above namely is the result of sensitivity by detecting only the test sample on the belt. The sensitivity would be affected according to the products being detected, working condition and also the different positions the metal mixed with.

3. Detecting capacity per hour is related with product weight, the value of the table is according to the density of water (1000kg /m3).

4. We much appreciate if you attach the filled product info questionnaire with your enquiry.

Size Layout