Overcoming the Metal Detection Challenge of Meat's Physical Properties

Processing meat products is inherently fraught with risks that present product quality and safety challenges to food processors. In addition to preventing biological contamination, food processors must also ensure the right processes and equipment are in place to avoid the possibility of unwanted foreign objects entering their process at any stage, including when supplier ingredients are added.

We have discussed in the past how product inspection equipment systems – including industrial food metal detectors and X-ray inspection systems — can help provide food manufacturers with the performance and service they need to detect foreign objects in food and improve the quality and safety of their products.

However, detection of such physical contaminants can be difficult with metal detection technology because meat products have high “product effect”—meaning they have conductive properties that can mimic a foreign object, and cause the detector to incorrectly signal a physical contaminant. This false positive often necessitates a compromise in sensitivity to avoid false rejections. With temperature, salt content and product size changing during processing, product effect can vary, too, making consistent foreign object detection difficult. It also poses an ongoing challenge to avoid excessive false rejects which increase the potential for costly scrap or rework.

We’ve talked about product effect before in our How to "Beat The Challenge of Baked Bread’s Physical Properties During Inspection article". Warm bread coming out of the oven, coupled with its salt content, tends to have a high product effect as well. This negatively impacts the metal detector’s ability to distinguish between actual non-ferrous metal contaminants and the false signal given by the combination of typical product attributes. This is further complicated by the varying densities, air bubbles and other physical characteristics of each loaf, since no two are exactly the same. (There also are variations between bread types.) We’ve also outlined how dairy products can face the same types of challenges.

Most meat-based products will exhibit high product effect in an electromagnetic field resulting in metal detection performance significantly worse than detecting contaminants in dry, inert products. Some examples of challenging meat applications are:

Spiced and salted processed products

Deli-style layered slices

Sausages

Moist or bloody whole muscle cuts

Ready to eat meals containing meat

A package of meat can be highly conductive due to its moisture content. If salt is present – which is common in ready-to-eat or processed meat products — conductivity is even higher. When this product passes through a metal detector the excitation signal can create a strong product effect that requires compensation. Food metal detectors must ignore this product effect to avoid a false rejection.

A metal detector that utilizes multiple frequencies is an option that should be considered. Multi-frequency metal detection technology, scans a combination of up to five user selectable frequencies from 50 to 1000 kHz. This multiscan metal detector enables users to identify contaminants that are up to 70% smaller in volume than was previously detected on single and dual frequency detector technologies, reducing the probability of escaping detection to near zero. It is like having five metal detectors in one, to provide unmatched sensitivity and the highest probability of finding ferrous, non-ferrous, and stainless steel metal contaminants in challenging meat applications with high product effect.

A common approach to reducing product effect of meats and thereby improving detection performance is to utilize low-frequency, low-energy excitation. When a difficult product is encountered, a technician utilizing multiscan technology can set up a low frequency schedule better suited to a highly conductive product and optimize performance.

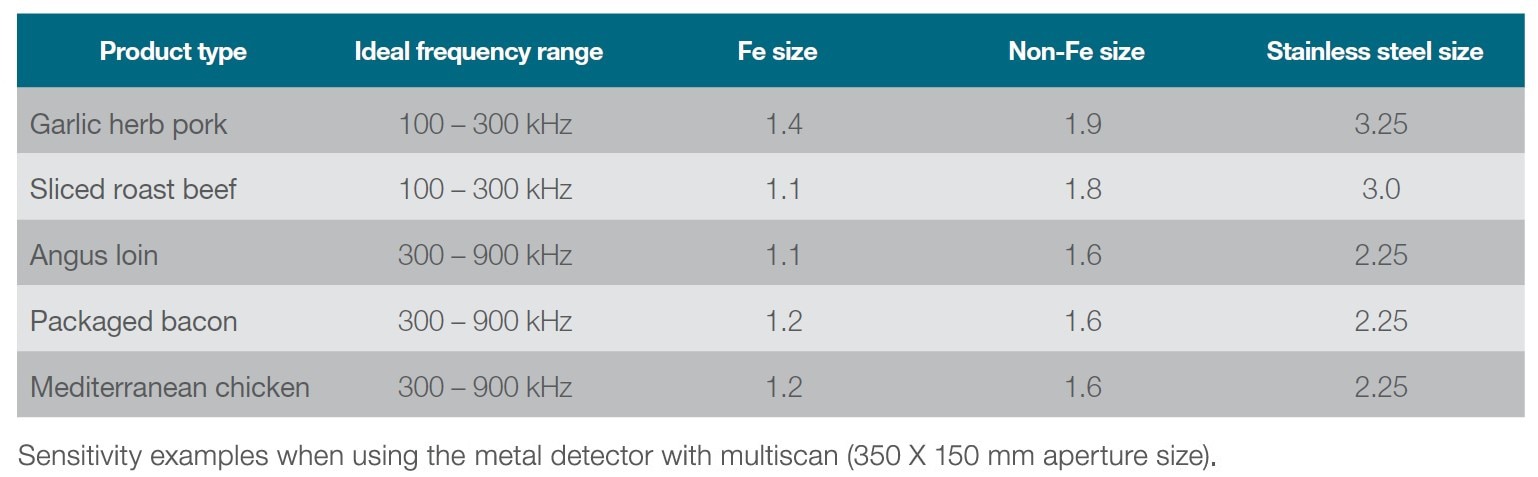

We’ve outlined examples of sensitivity with regard to product type, ideal frequency range, and metal sizes below:

Multiscan metal detectors typically exceed the performance of single frequency metal detectors by 10-30%. Because the frequencies are completely adjustable, the multiscan metal detector is more flexible and can cover a wider range of applications.

For more details about inspection in the meat processing industry, please contact our sales engineer @ fanchitech@outlook.com